With the rapid development of intensive and large-scale farming, about 1m3 of chicken manure is produced per 10,000 chickens per day. If the chicken manure is not treated in a timely and effective manner, it will not only affect the surrounding environment of the chicken farm, but also affect the health of the chickens. There are various ways to treat chicken manure. At present, the common methods are fermentation treatment (commonly used are turning machine turning and fermenting tank), drying treatment and so on. In terms of the current market development trend, the following is a brief introduction to the drying method of chicken manure.

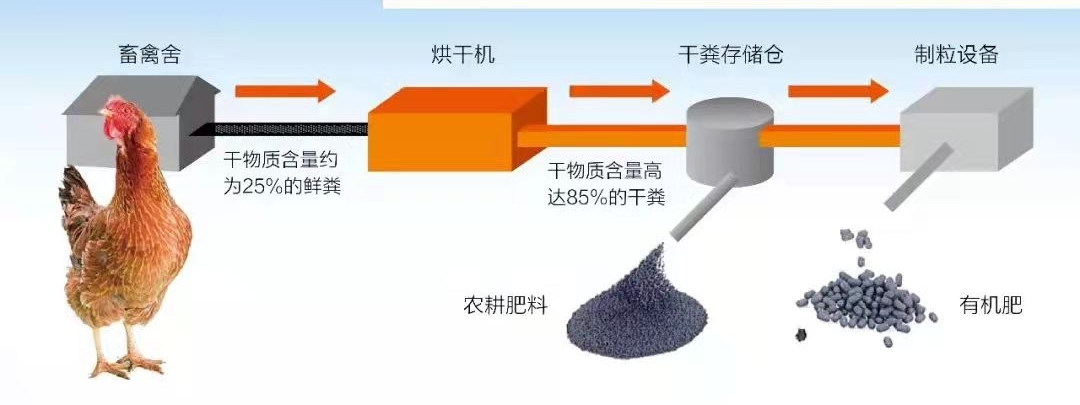

Process layout of drying treatment (take 100,000 laying hens as an example)

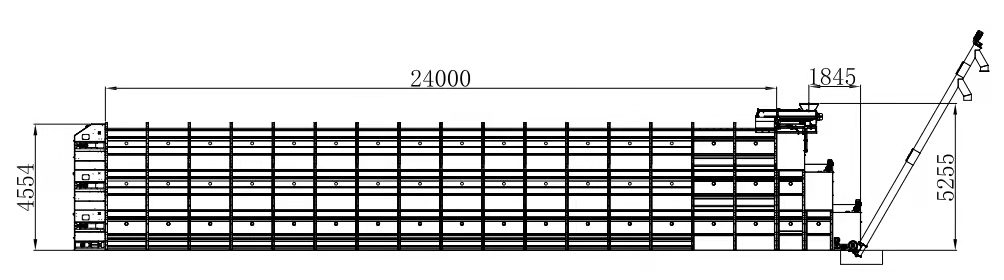

The drying equipment covers an area of about 5.5 meters wide and 45 meters long. The distance to the fan wall of the chicken house is about 5 meters. There are 6 layers of manure boards, and the height of each layer is 700mm.

Process flow of drying treatment

1. Transfer the fresh chicken manure in the chicken house (the moisture content of fresh chicken manure is about 75%) to the drying equipment through the oblique manure cleaning equipment.

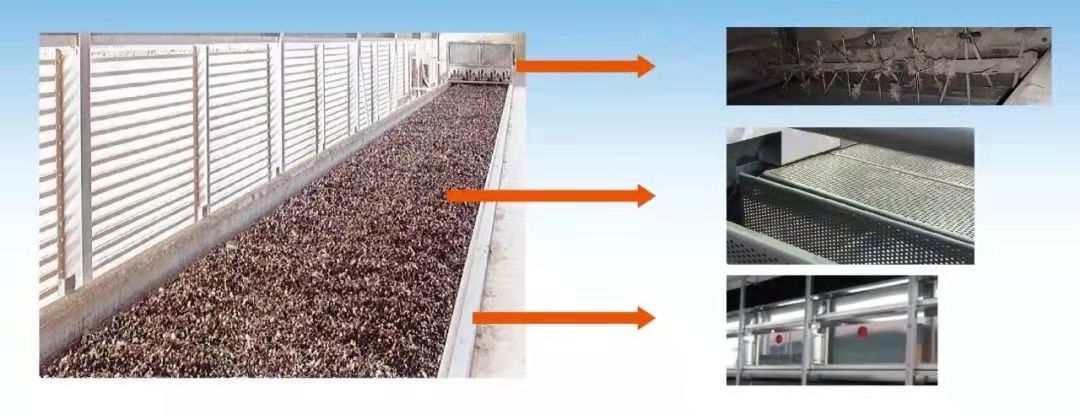

2. The chicken manure is evenly scattered on the sixth layer of the manure board of the equipment through the swinging funnel. The wet chicken manure starts to dry from the top layer of the manure board, and the hot air passes through the manure board and the material by pulling or pushing force.

3. Regularly transfer the sixth layer of chicken manure to the fifth layer, the fifth layer of chicken manure to the fourth layer… The second layer is transferred to the first layer, turn on the side wall drying fan, every cycle Drying runs for 3 hours, 6 cycles per day.

4. After 6 cycles of drying, the chicken manure will reach the first layer. The final moisture content of the chicken manure is about 15%. The dried chicken manure is transported to the composting workshop through the auger, and the chicken manure is processed by drying. After that, the purpose of dehydration, deodorization, insecticide and sterilization is achieved.

5. The processed chicken manure is packaged or loaded for sale.

6. In the rainy season or high-humidity weather, the outdoor air and the air in the chicken house are insufficient in heat, and an external heat source is required to heat the air to ensure the drying effect.

Advantages of drying chicken manure

1. The drying equipment is composed of many smooth perforated steel plates, which are safe and firm, and can support poultry manure with a thickness of 15-18cm to ensure the efficient operation of the drying process.

2. The drying equipment can be fully automated within 7 days a week and 24 hours a day without monitoring; the chicken manure can be evenly dispersed on the manure board.

3. The drying equipment makes full use of the outdoor hot air and the hot air in the chicken house to evaporate the moisture in the chicken manure, reduce the microbial fermentation of chicken manure in the chicken manure, and reduce the concentration of ammonia gas, thereby reducing the pollution to the surrounding environment.

4. Drying and processing chicken manure can reduce the emission of dust from the chicken house and reduce the pollution to the surrounding environment.

5. Drying and processing chicken manure reduces the conversion and emission of ammonia gas, which is beneficial to retain organic nitrogen in chicken manure and improve the utilization value of dry chicken manure.

6. The dried chicken manure can also be directly fed into the granulation equipment for granulation to obtain high-quality chicken manure granules.

7. The dried chicken manure can also be directly used as the basic fertilizer for various crops.

8. The degree of mechanization and integration is high, and the equipment occupies a small area.

Motong Machinery has been adhering to the corporate mission of making farming simple, reliable, environmentally friendly and efficient, developing products with innovative ideas, and continuously providing customers with professional products and standardized services.

Post time: Feb-18-2022