1. Heating equipment

As long as the purpose of heating and heat preservation can be achieved, electric heating, water heating heating, coal stoves and even kang, floor heating and other heating methods can be selected, but it should be noted that the heating of coal stoves is dirty and prone to gas poisoning, so a chimney must be added. Pay attention to thermal insulation when designing the house.

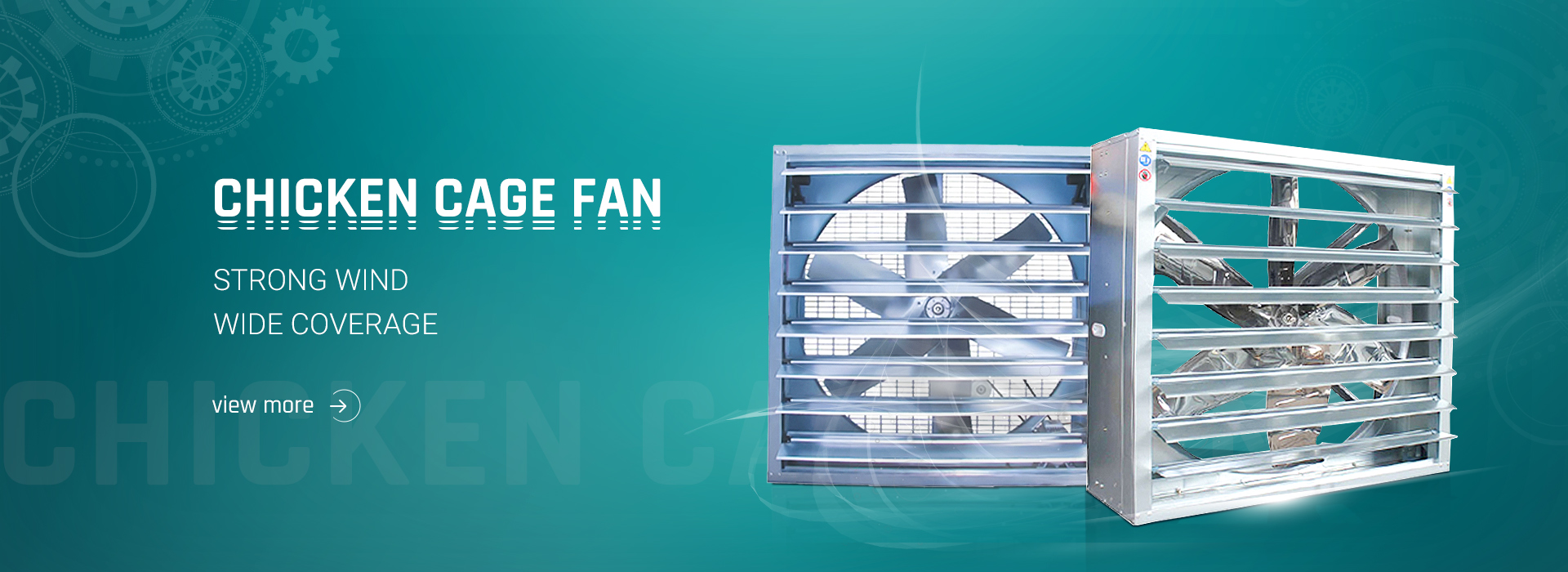

2. Ventilation equipment

The closed chicken house must be mechanically ventilated. According to the direction of airflow in the house, it can be divided into two types: horizontal ventilation and vertical ventilation. Horizontal ventilation refers to the direction of airflow in the house that is perpendicular to the long axis of the house, and vertical ventilation refers to a ventilation method in which a large number of fans are concentrated in one place, so that the air flow in the house is parallel to the long axis of the house.

Research and practice since 1988 have proved that the effect of longitudinal ventilation is better, which can eliminate and overcome the phenomenon of ventilation dead corners and small and uneven wind speed in the house during transverse ventilation, and at the same time eliminate the drawbacks of cross-infection between chicken houses caused by transverse ventilation.

3. Water supply equipment

From the point of view of saving water and preventing bacterial contamination, nipple drinkers are the most ideal water supply equipment, and high-quality water-tight drinkers must be selected.

Nowadays, the most common use of cage-bred adult chickens and laying hens is V-shaped sinks, which often run water for water supply, but spend energy every day to scrub the sinks. Pendant-type automatic drinking fountains can be used when raising chicks horizontally, which is both hygienic and water-saving.

4. Feeding equipment

The feeding trough is mainly used, and the caged chickens all use long through troughs. This feeding method can also be used when brooding flat, or the hanging bucket can be used for feeding. The shape of the feeding trough has a great influence on the throwing of the feed for the chickens. The feeding trough is too shallow and there is no edge protection, which will cause a lot of feed waste.

5. Egg collection equipment

Chicken farms with a high degree of mechanization use conveyor belts to collect eggs automatically, which has high efficiency but a high breakage rate. In October, chicken farmers generally collect eggs by hand.

6. Manure cleaning equipment

General chicken farms use manual and regular manure removal, and larger-scale chicken farms can use mechanical manure removal.

7. Cage

The brooding can be done with a mesh board or a three-dimensional multi-layer brooder; in addition to the flat net feeding, the bred chickens are mostly raised in overlapping or stepped breeding cages. Laying hens are basically caged. At present, there are many domestic manufacturers of chicken cages, which can be purchased according to the actual situation. The area of the chicken cage must be guaranteed.

8. Lighting equipment

In China, ordinary light bulbs are generally used for lighting, and the development trend is to use energy-saving lamps. Many chicken farms install time-controlled switches to replace manual switches to ensure accurate and reliable lighting time.

9. Incubation equipment

Incubation equipment refers to the general term for the items required in the incubation process, including: incubators, hatchers, incubator accessories, special items for incubators, heating equipment, humidification equipment, and various measurement systems, etc.

10. Disinfection equipment

Agricultural sprayers, air pumps, etc.

11. Immunization and treatment equipment

Continuous syringes, pricking needles, etc.

12. Beak cutting equipment

Electric beak trimmer, electric soldering iron, etc.

13. Weighing equipment

Spring scales, steelyard scales, electronic scales, etc.

Post time: Aug-17-2022